Car Body Dies

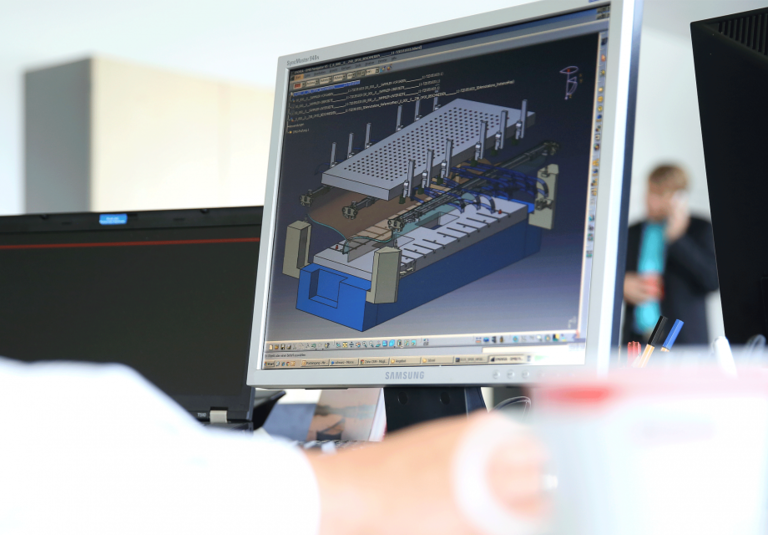

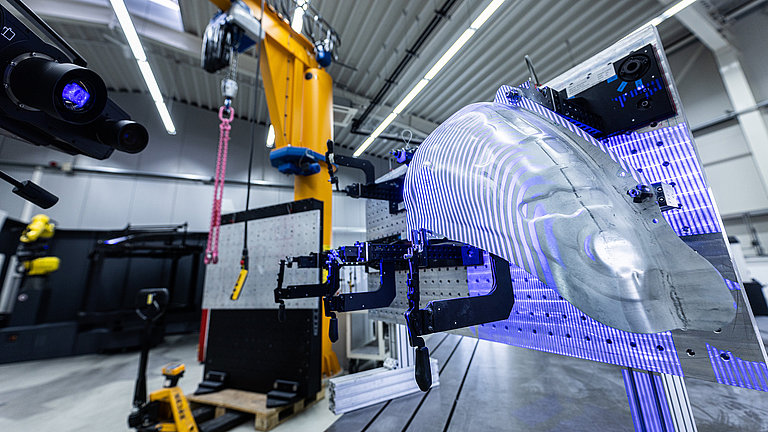

As a card body dies manufacturer, we specialise in the production of car body moulds. We understand the importance of these tools in the automotive industry and are constantly working to improve our technology and develop new methods of producing moulds with greater accuracy and efficiency. We pride ourselves on producing high-precision tooling that can withstand the high stresses and demands of the stamping process, while maintaining the precision and accuracy required to produce high-quality body panels. With the increasing demand for fuel-efficient and lightweight cars, the development of new moulds to produce these cars is becoming increasingly important. Overall, body moulds play a crucial role in the automotive industry and we are proud to contribute to the production of high quality cars.

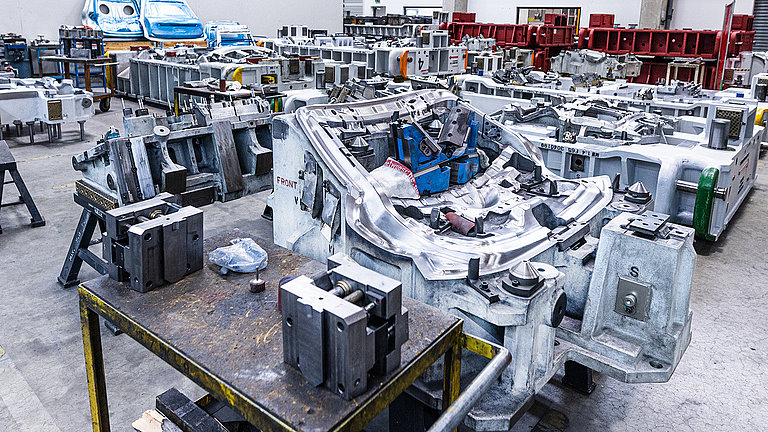

Structural parts are our daily business. Whether steel or aluminium, our employees know what it takes. In addition to the classic transfer or tandem moulds, we also feel particularly at home with complex structural parts such as tailgates, wheel arches or end lights. By the way, the place of use does not matter, our team works in all tools worldwide at your site.

Blank cutting tools are made to customer specifications with an accuracy of 0.01 mm cutting clearance. Thanks to our specially designed universal shears, there are hardly any limits to requirements and solutions. Experts in our company assemble the tools and work them into our customers' pressing plants.

Further information in our brochure

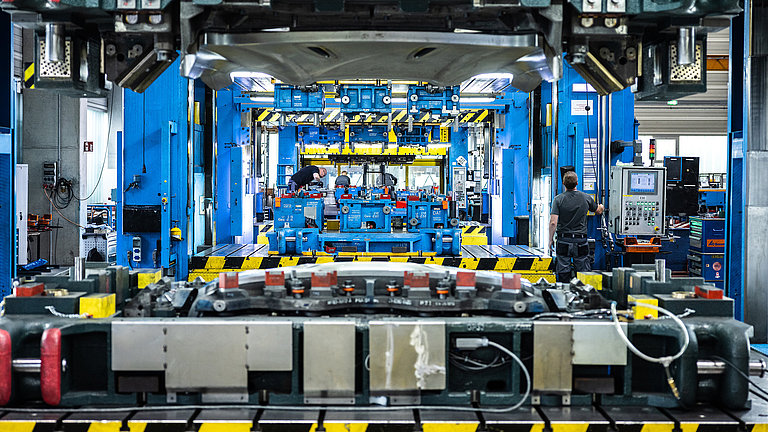

Hydraulic press Loirsafe 30.000 KN

| Maximum pressing force | 1.000 to 30.000 kN |

| Plunger cushion | 400 to 4.000 kN |

| Table cushion | 600 to 6.000 kN |

| Table size | 5.000 x 3.000 mm |

| Installation height | 800 to approx. 2.500 mm |

| Working speed | |

| 1st stage with 2 cylinders | 135 mm/s (to 5.700 kN) |

| 77 mm/s (to 10.000 kN) | |

| 2nd stage with 6 cylinders | 44 mm/s (to 18.400kN) |

| 24 mm/s (to 30.000 kN) | |

| Stand opening (lateral) | 2.000 to 1.100 mm |

| Stand opening (front) | 5.100 mm |

| Stand opening (front) | SPS S7 |

Hydraulic press Loirsafe 30.000 KN

| Maximum pressing force | 1.000 to 30.000 kN |

| Plunger cushion | 400 to 4.000 kN |

| Table cushion | 600 to 6.000 kN |

| Table size | 5.000 x 3.000 mm |

| Installation height | 800 to approx. 2.500 mm |

| 8-point drawing cushion | |

| Working speed | |

| 1st stage with 2 cylinders | 135 mm/s (to 5.700 kN) |

| 77 mm/s (to 10.000 kN) | |

| 2nd stage with 6 cylinders | 44 mm/s (to 18.400kN) |

| 24 mm/s (to 30.000 kN) | |

| Stand opening (side) | 2.000 to 1.100 mm |

| Stand opening (front) | 5.100 mm |

| Siemens control | SPS S7 |